Surface Finishes & Edge Profiles:

Surface Finishes & Edge Profiles directly effect the appearance of the final product greatly. The change from one type to another in an otherwise identical product will result in a drastic change in asthetic and how well it matches your chosen architectural style. Please consult with us if you have questions about what finish type and profile is suitable to end goal. For the benefit of iPad users who can't use drop down menus, the following are links to the relevant areas:

Surface Finishes:

There are numerous surface finish types available to produce a highly tailored look and style for almost any desired application; the following aspects of surface treatments can be applied in graduated increments to produce a high degree of customization:

- Stains & Color Alteration: Prior to sealing, almost all of our products can take and hold various degrees of stain and coloration. The degree to which staining will affect the final product is determined by the initial color and movement (visual grain) of any particular stone type. Light colored stone with muted movement can be altered the most, while strongly colored stone can be altered to lesser degrees. A general rule is that stone can be made darker but not lighter and colors can be altered additively but not subtractively (ie, Red can be made a darker Red or Purple but NOT Blue). The lighter and closer to white the raw material, the higher the degree of control over the final color and shade in the final product. Since stains are formulated on a case by case basis to produce the best possible result, we don't provide a standardized color chart; please inquire as to availability of various colors in specific stone types. As long as the colors are natural and applied subtly, stained material is indistinguishable from unstained material.

- Surface Texture: We can provide various degrees of surface "roughness" to create a number of desired appearances along several different gradients. For example, at one extreme we can hone and polish a material to an entirely smooth honed surface; on the other end of the spectrum, we can leave the finished surface totally unfinished to appear as if the stone is completely natural. Additional, we can cleft some materials along the grain to produce a rough but level surface. In between these two extremes we have another surface finish we refer to as "Cathedral Finish" where a rough stone is honed to various degrees to create the appearance that the stone was hewn and placed rough, but worn away by centuries of foot traffic to a smooth but wavy surface. In many old stone cathedrals you can see a similar affect, hence the name. This can be applied subtly to floors and countertop to create an antiqued look.

- "Wetness" and Gloss: We can apply different treatments to the stone to create "wetness" in various degrees. When stone is raw and unfinished, the many grain layers (movement) are extremely muted. When water is applied to this raw stone, it will bring out the movement in detail. We have special treatments to create finished, sealed products that will not stain and shed water without appearing wet. This is useful in applications where it is desired that the stone appears totally natural, such as outdoor walkways. On the other end of the scale, we can apply treatments that make dry stone look wet all the time. This can produce stone products where the grain is brought out and made highly visible, as well as a high gloss. In between these extremes, we can treat the stone to bring out the movement but keep the stone from appearing very glossy.

- Sealing & Weather Proofing: All of our products are impregnated with polymers to prevent staining and maintain the material finish after staining and wetting are applied. While not totally unaffected by UV light and extreme weathering, our finishes are extremely durable and will last almost indefinitely as long as the material isn't abused enough to break through the sealant; such as by leaving strong acids/bases on the material or deep scratches. Finished Sandstone and Limestone with an intact seal will NOT stain. For demanding applications, please consult with us for the best choice in materials and treatments.

Edge Profiles:

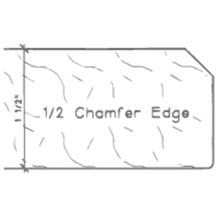

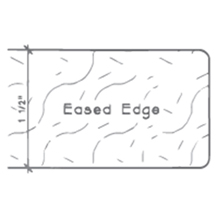

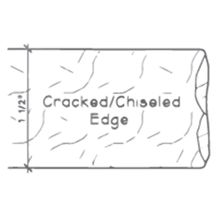

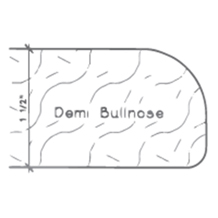

One of the most distinctive features of stone slab work is determined by what edge style is applied. The chosen edge can completely change the feel of a countertop, hearth, etc. from one architectural style to another; especially waterfall edges and laminated edges (not shown). A "Waterfall Edge" is when a piece of mirrored slab is nearly invisibly mitered and joined to a corresponding mitered slab to create a large vertical piece that continues downwards for some way, creating the appearance of a piece of stone bent at the edge; these are most commonly applied in modern styles of architecture. A laminated edge is when a strip of slab is joined underneath the edge of a slab to create the appearance of a much thicker slab; thick slabs can be carved out to create the same effect out of a monolithic block but this is not usually necessary. Other edge types are also available and as every piece out of our shop is custom made for each clients needs, please inquire if you'd like an edge type not shown. The following edges are illustrated as applied to a 1.5" slab, the most common slab thickness but, can be applied to thicker or thinner slabs subject to some limitations:

Chamfer

Chamfer Dupont

Dupont Classic Ogee

Classic Ogee Eased Edge

Eased Edge Cracked or Chiseled Edge

Cracked or Chiseled Edge Full Bullnose

Full Bullnose Demi Bull

Demi Bull Regular Ogee

Regular Ogee